Process Mapping is a foundational capability for any organisation—whether in manufacturing, healthcare, government, or the non-profit sector—committed to achieving Enterprise Excellence. It enables people at all levels to truly “see” their work—the good, the bad, and the opportunity-rich—through tools like value stream mapping, SIPOC mapping, and workflow optimisation. When integrated into your strategic planning, daily management systems, and continuous improvement frameworks, process mapping becomes a key enabler of cultural transformation and sustained performance improvement across both industrial and social sectors.

Why Process Mapping Matters

Most organisations are busy—work gets done, issues are solved, and targets are pursued. However, beneath the surface, many systems remain fragmented, inefficient, and reactive. Process mapping matters because it brings much-needed visibility to these hidden complexities.

Process Mapping creates visibility. It uncovers the hidden complexity in the way work is performed and gives teams the clarity to address it. Teams learn to identify:

- Waste in the form of delays, rework, duplication, or excessive handovers

- Unevenness in how workload is distributed across people or time

- Bottlenecks that constrain flow and customer delivery

- Opportunities for simplification, automation, or better coordination

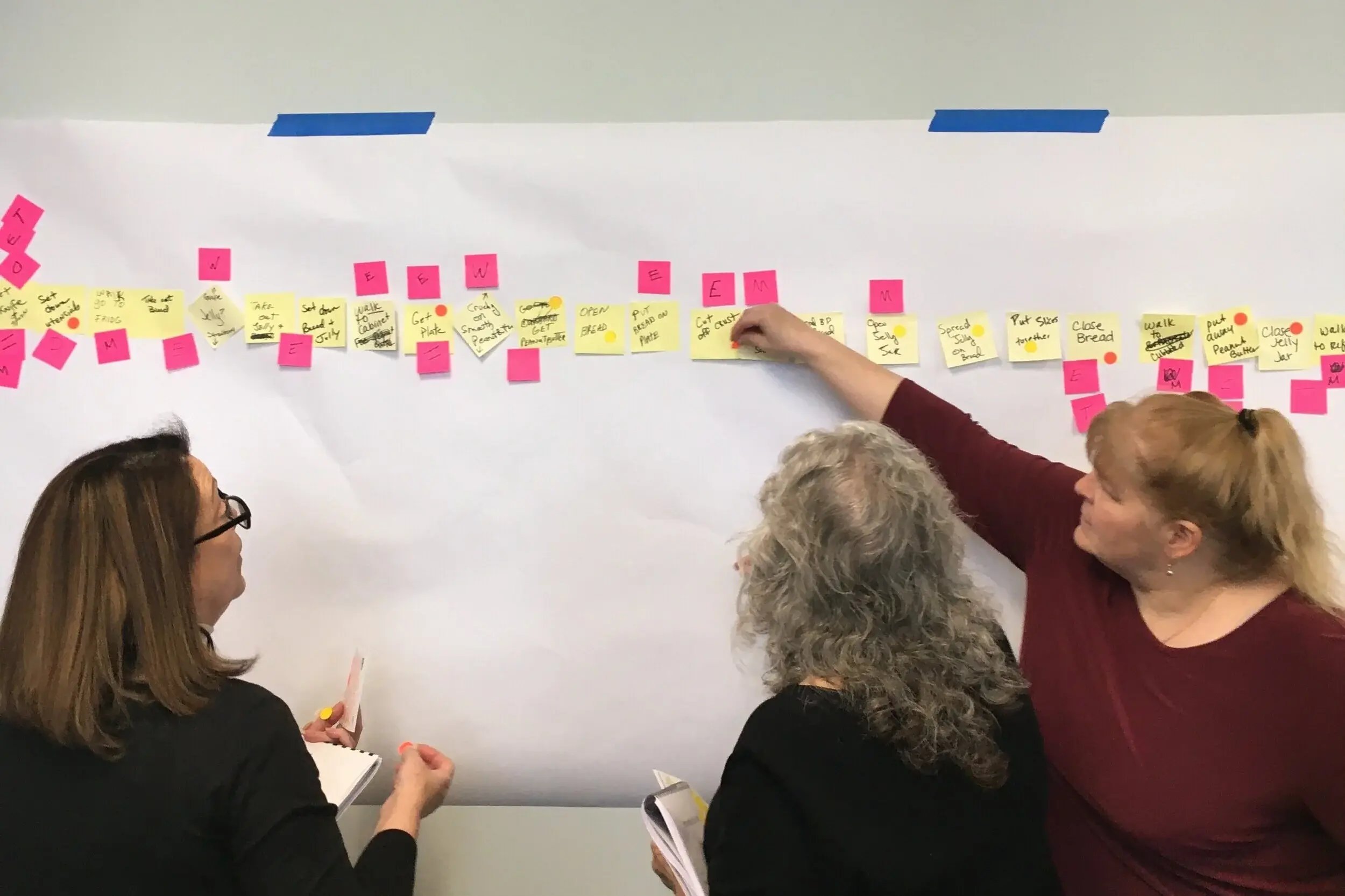

More than just a tool, process mapping is a collaborative learning method that fosters cross-functional alignment, deepens empathy for internal and external customers, and unlocks lasting, practical improvements.

The Process Mapping Methodology

Most successful process mapping efforts follow a structured seven-step approach, widely used in manufacturing, healthcare, public services, and non-profit organisations to drive continuous improvement, reduce waste, and enhance service delivery:

Include team members who perform the work, those who support it, and those accountable for results. A diversity of perspectives is critical in sectors like industrial operations, healthcare delivery, or community services to ensure a comprehensive view of the process.

2. Clarify Purpose and Customer Expectations

Define the intent behind the mapping session. Are you improving production efficiency, patient care, public sector workflows, or non-profit program outcomes? Align with strategic goals and gather Voice of Customer (VoC) data where possible to stay customer-focused.

3. Go to the Gemba – Walk the Process

In line with Lean thinking, observe the actual work where it happens—whether it’s on the factory floor, in a hospital ward, or at a community service site. Engage directly with staff to understand bottlenecks, handoffs, and barriers to flow.

4. Map the Current State Visually

Use value stream mapping, SIPOC, or simple flowcharts—whether physical or digital—to visualise the process. Focus on what truly happens, not the idealised version. This step is crucial for both process optimisation in manufacturing and workflow clarity in social services.

5. Identify and Capture Improvement Ideas

Facilitate discussion on pain points and improvement opportunities. Whether you're aiming to reduce wait times, eliminate duplication, or smooth out production flows, capturing the team’s insights unlocks hidden potential.

6. Prioritise Improvements

Use prioritisation tools to assess potential improvements based on impact, effort, and alignment to business or mission goals. This helps build a realistic and meaningful improvement roadmap, essential in both industrial settings and resource-limited public sectors.

7. Map the Future State

Design the improved process with lean principles in mind. This future state map becomes the foundation for your continuous improvement plan, guiding implementation in everything from production systems to community-based service delivery.

Process Mapping Techniques We Use

At the Enterprise Excellence Group, we help organisations build capability in a wide range of mapping techniques. Each one is chosen based on the context, goals, and people involved.

1. Customer Journey Mapping

Understand the experience of your customers—from first interaction to fulfilment and beyond. This approach surfaces emotional highs and lows, pain points, and handoff issues. It aligns internal teams around delivering better service and value.

2. Value Stream Mapping

Originally developed for manufacturing, VSM is now used across sectors. It maps the end-to-end process flow and highlights key metrics such as lead time, cycle time, wait time, and value-added time. It is ideal for identifying waste, constraints, and improvement priorities.

3. Four Field (Swim Lane) Mapping

Best suited for service, office, and knowledge-based processes. This method shows how work flows across departments or roles, capturing interactions, bottlenecks, and rework loops. It is invaluable for clarifying accountability and improving collaboration.

4. SIPOC Mapping

SIPOC Mapping provides a clear, high-level overview of a process by outlining its Suppliers, Inputs, Process steps, Outputs, and Customers. It’s an effective tool for aligning teams early, helping everyone understand the end-to-end process and agree on what success looks like. This clarity supports more focused improvement and stronger stakeholder alignment.

When to Use Process Mapping

Process Mapping is valuable in many situations, including:

- As part of your strategic improvement cycle

- When customer feedback signals frustration or inconsistency

- During system implementation or automation planning

- To reduce cost, delays, or complexity

- To align cross-functional teams around a shared understanding of how work gets done

How We Can Help

Facilitated Mapping Events

We design and run mapping sessions that are customised to your organisation’s specific goals, challenges, and industry context. Whether it’s value stream mapping, process mapping, or SIPOC, we engage cross-functional teams to uncover inefficiencies, align stakeholders, and co-create practical improvements. These sessions are highly interactive and outcome-focused, generating immediate insights and ownership of solutions.

Train-the-Trainer Capability Building

To ensure sustainability, we offer comprehensive train-the-trainer programs that equip your internal leaders with the skills and tools to facilitate future mapping events.

Participants learn not only how to lead effective sessions, but also how to engage teams, manage group dynamics, and link mapping to broader improvement efforts. This approach builds internal expertise and drives long-term cultural change.

Integrated Mapping within Strategic Planning & Daily Management

Mapping shouldn’t be a one-off event. We help you embed it within your strategic planning, project prioritisation, and daily management systems to keep the momentum going.

By linking process clarity to business priorities and performance tracking, mapping becomes a routine part of how work is improved, decisions are made, and results are delivered.

If you'd like to configure a Process Mapping event, fill out this form and we'll get back to you.

Empower Your Teams.

Align your processes. Accelerate your results.

Talk to us about bringing structured, impactful mapping into your strategy and daily operations.

👉 Contact us today to discuss your Process Mapping idea.

.svg)