At the Enterprise Excellence Group, we help organisations move beyond surface-level fixes. Our Root Cause Analysis (RCA) approach equips your teams to uncover the real reasons problems occur—so you can solve them for good and build a culture of continuous improvement.

What is Root Cause Analysis?

Root Cause Analysis (RCA) is a problem-solving method used to identify the fundamental or underlying reasons why a failure or incident occurred. It helps prevent future occurrences of the same issue by enabling long-term corrective actions rather than temporary fixes.

What Happens When RCA Is Missing?

Without proper RCA, organisations often fall into costly patterns. Reoccurring issues resurface, wasting time, energy, and resources. A blame culture where people point fingers rather than fixing the problem, money is wasted on fixes that don't work and valuable learning and improvement opportunities are missed.

Benefits of Root Cause Analysis

Organisations that adopt effective RCA practices see transformative results:

Sustainable Results

Problems are fixed once—and stay fixed.

Improved Performance

Reduction in downtime, defects, delays, and cost.

Engaged Teams

Employees feel empowered and capable of solving challenges.

Stronger Culture

RCA fosters ownership, accountability, and collaboration.

Smarter Systems

Processes are continually improved, not just maintained.

Our Unique Offering: Beyond Tools to Capability and Culture

At the Enterprise Excellence Group, we don’t just teach tools—we build capability and mindset.

Here’s what makes our RCA approach different:

1. Whole-System Alignment

We integrate RCA into your broader operational excellence system, ensuring leadership, culture, and systems all support sustainable improvement.

2. Engaging and Practical Learning

Our hands-on training workshops embed RCA thinking through real examples from your business. We tailor the process to your people, your environment, and your goals.

3. Simplicity and Impact

We cut through the complexity and provide a practical, visual method that everyone can use—from frontline teams to executives.

4. Proven Frameworks and Tools

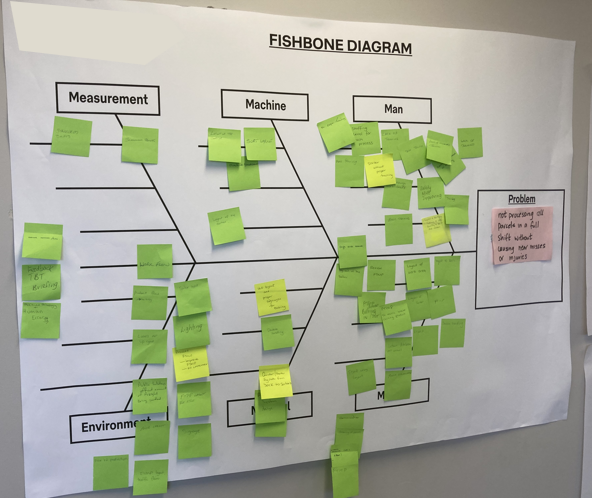

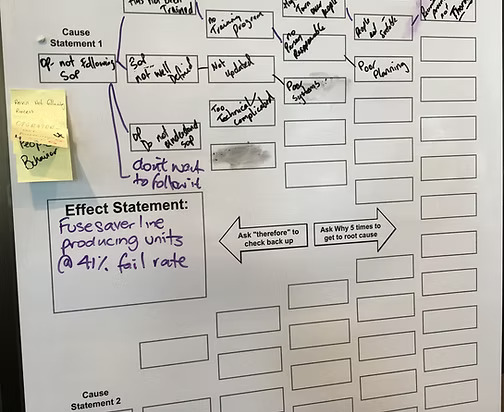

We draw from globally recognised methodologies such as 5 Whys, Fishbone (Ishikawa), 4M, and Human Factors Analysis—blended into a practical RCA system your team can sustain.

5. Long-Term Partnership

We don’t walk away after a workshop. We help your team implement, reflect, and continually improve RCA capability over time.

We have 6 Enterprise Excellence Podcast episodes for you.

Click on the images below to listen :)

178 Why is transforming our enterprise into a lean, mean fighting machine essential to compete with AI? With author Brady Brim-DeForest

156 How to deploy lean projects and more with author Michael Balle.

154 How Senior Leaders can transform their organisation with the Pioneer of Lean, Mark Deluzio.

#91 Ian Glenday – Breaking through to Flow and Lean RFS, Part 1

92 Ian Glenday – Breaking through to Flow and Lean RFS, Part 2.

RCA Workshop

Learn How To:

Build Capability.

Solve Real Problems.

Create a Culture of Continuous Improvement.

Details about the Workshop

What You'll Experience

This one-day, immersive simulation-based workshop is designed to be practical, engaging, and directly relevant to your operational environment.

Participants will learn how to:

-

Use the A3 Problem Solving process to structure thinking and align teams

-

Understand and apply Root Cause Analysis (RCA) methods such as 5 Whys and Fishbone

-

Define and track Key Metrics to measure impact and success

-

Identify and implement effective Countermeasures

-

Align problem solving with your organisation's Core Values

-

Recognise and reinforce desired behaviours using Recognition Cards

All of this is taught through a realistic simulation game, where participants face challenges, collaborate in teams, and apply their learning to solve practical problems—just like they would in the workplace.

Who Should Attend

This workshop is ideal for:

-

Processing or factory team members and their leaders

-

Administration team members and their leaders

-

Anyone responsible for solving problems or leading improvement in their area

It’s designed for both operational and support roles across industries such as manufacturing, supply chain, logistics, services, and more.

Workshop Duration & Inclusions

🕒 Duration:

-

1 full-day interactive workshop

-

Plus 2 x 1-hour external coaching sessions per organisation to reinforce learning and support application

💰 Cost:

-

$900 AUD (incl. GST) per participant

-

10% discount for groups of 3 or more

-

Includes workbook, handouts, lunch, morning and afternoon tea

FACILITATOR: Mr Paul Deane, Managing Director LeanBites

E: paul@leanbites.com.au P: 0413288157

Paul is an innovative Continuous Improvement Facilitator, with strengths in operationalising LEAN systems, manufacturing best practice and Problem Solving. CSSC/ISSP certified, 6 Sigma Black and Green Belts, with over 18years of Lean implementation across large and small organisations.

![Photo fishbone 1[90]](https://enterpriseexcellencegroup.com.au/hs-fs/hubfs/Photo%20fishbone%201%5B90%5D.png?width=649&height=484&name=Photo%20fishbone%201%5B90%5D.png)

The workshop in action

We don't currently have a workshop available, but you can request one using this form.

Ready to Solve for Good?

If you're tired of recurring issues and want to embed a system of true problem-solving in your organisation, let’s talk. We’ll work with you to tailor an RCA journey that suits your needs and empowers your people.

👉 Contact us today to discuss your RCA goals

.svg)